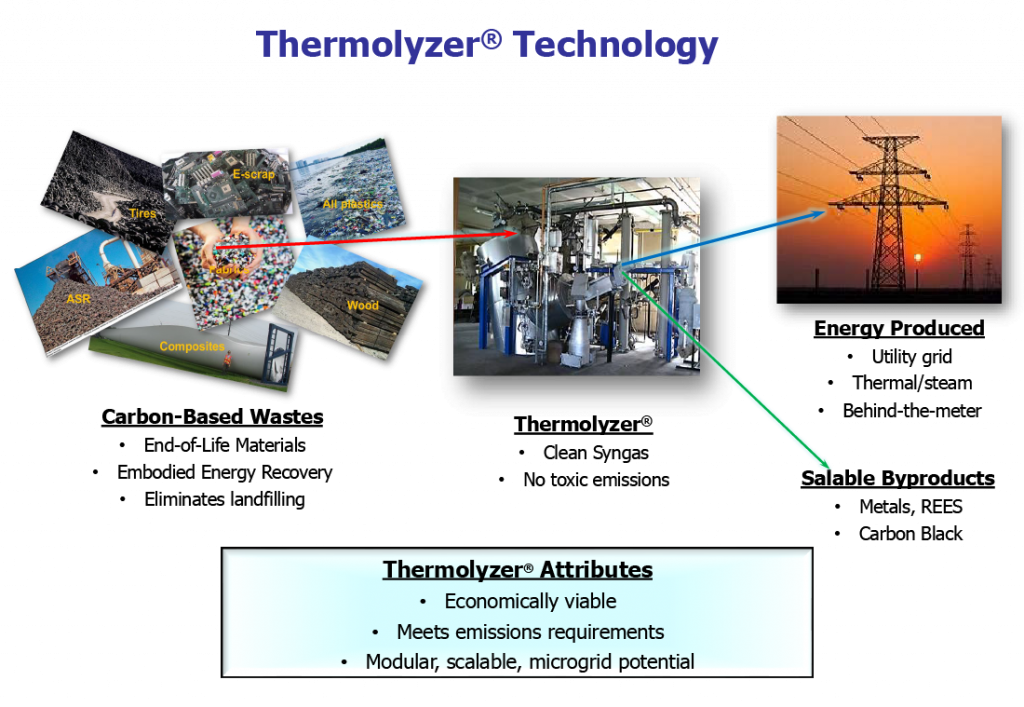

Operating continuously and energy self-sufficient after startup, the system eliminates hazardous compounds while recovering metals, rare earths, and carbon-based materials. The hydrogen-rich syngas can fuel steam boilers, gas turbines, or internal combustion engines, depending on the application. The modular, scalable design allows flexible deployment and customization based on waste type and volume—making Thermolyzer® an ideal recycling solution. |

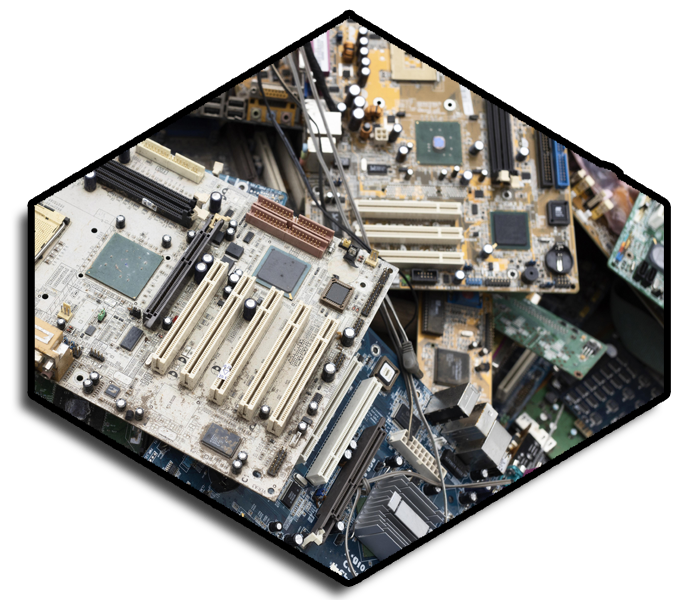

Many hazardous or otherwise non-recyclable materials can be processed as a source of clean energy: electronic waste, tires, all types of plastics, railroad ties, auto shredder residue, composites and wind turbine blades, carpet, and more. Even the plastic littering our oceans and waterways is a viable feedstock for this groundbreaking technology.

The Thermolyzer® design is flexible. The modular design comes in a variety of sizes and can be upgraded for more feedstock or modified to accommodate different feedstocks efficiently.

Sellable Byproducts

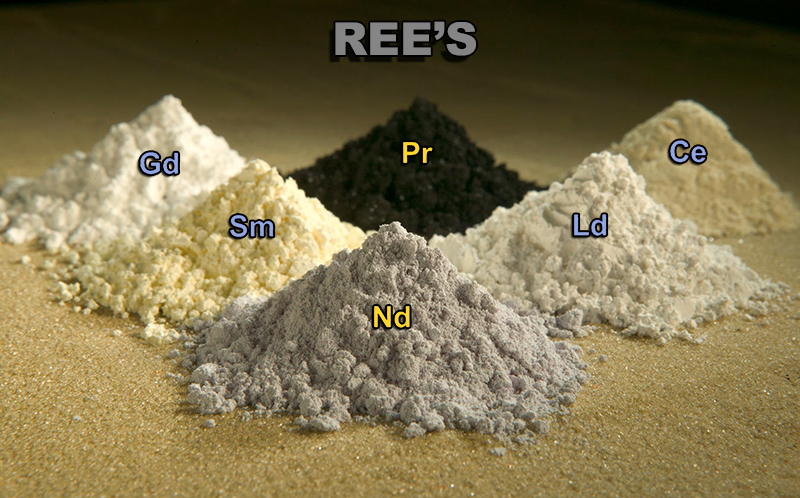

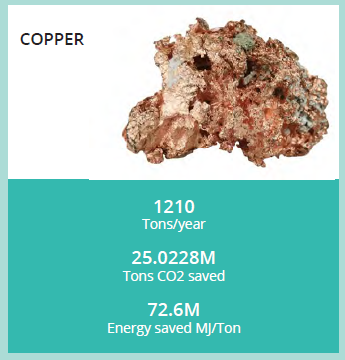

The Thermolyzer® technology not only provides clean energy and reduces waste, the technology but also produces sale-able byproducts that depend upon the feedstock.

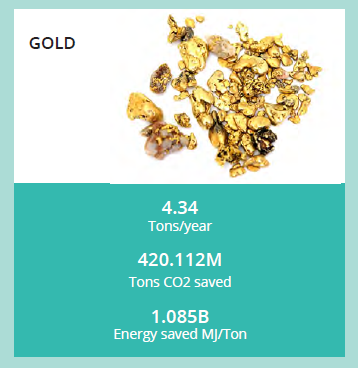

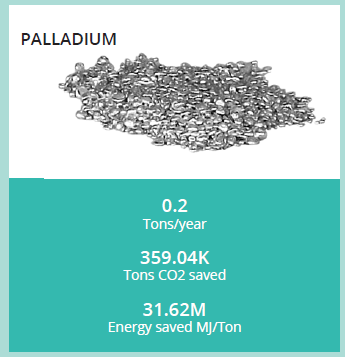

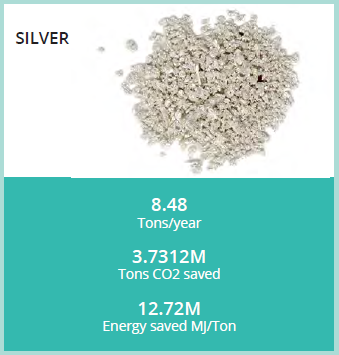

When a 10 ton per day Thermolyzer® processes electronic wastes, the byproducts are critical materials and REEs. Importantly, 62% of the elements found on the critical materials list are found in the clean metal stream from the Thermolyzer®. These include the expected gold, silver, palladium, and copper, but also nearly all or the REEs and other elements like gallium and antimony. All these elements are recovered for use in the U.S. and are not sent overseas. The syngas produced can run the entire plant.

For example, from tires the main product is syngas used for energy production and the byproducts are carbon steel and carbon black.

Independent Validations of Thermolyzer Technology